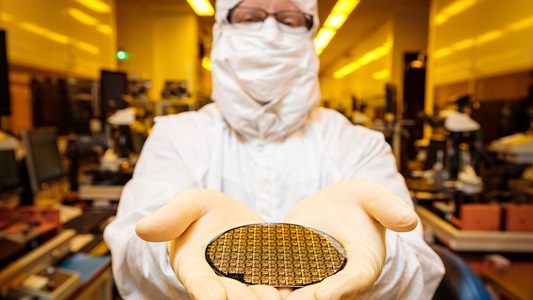

At the microelectronics foundry, engineers hover over wafers that enable a range of missions, from advanced satellite communications to complex astrophysics systems.

The Quick Chip

Tiny tech, big impact.

By: Rachael Tiehel

Size and Speed go hand-in-hand

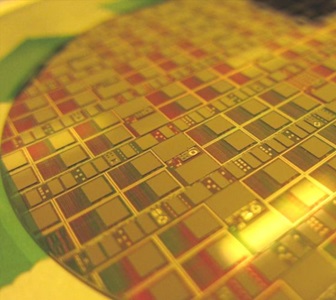

1,000 times faster than the chips in your cell phone, microscopic in size and enabling high speed secure communications for DoD missions. This was the ask Bill Deal took on, and it resulted in so much more: a super technology, housed in a tiny microchip, made by the Northrop Grumman Microelectronics Center (NGMC), and it’s called the Terahertz (THz) technology.

At a hundred times smaller than a grain of rice and one-tenth the width of a human hair, this chip operates at one trillion cycles per second; blowing by the speed of certain sound frequencies which seem to be moving at a glacial pace and averaging less than 100 cycles per second. Back in 2012 the record set for the ‘fastest microchip’ was 850 gigahertz, which seems pretty quick, yet THz is operating 150 billion cycles faster than that.

A challenging ask from DARPA

As the layers get peeled back on this story, it turns out developing the underlying technology behind the chip was one of the most challenging efforts of Dr. Bill Deal’s career, the consulting engineer who led the development of the terahertz microchip.

“When we started this effort, DARPA placed a DARPA-Hard challenge in front us which and we didn’t know if it was possible to achieve it. We bought together a team of microelectronics, manufacturing, materials and design experts to make this technology possible. Looking back, the effort took a team of more than a dozen PhD level experts, working closely together and supported by a large team of engineers and technicians to make this possible.” said Bill

The THz chip, manufactured at the NGMC Space Park Foundry, has held the Guinness World Record since 2014 for being the fastest microchip in production today. Speed is the name of the game for this technology, which astounds people when they witness its size, or ‘lack thereof.’

This tiny chip has many applications, like amplifying temperature signatures in our atmosphere so systems can capture critical weather information used around the world; forecasting and predicting climate change. It is also used in security imaging, high-speed secure communication functions and other data collection for Department of Defense Systems.

According to Bill, the terahertz integrated circuit and underlying technology is a unique capability in the US.

“We are currently working to insert this technology into NOAA’s SMBA system, used by the US for weather forecasting and NASA’s AOS Microwave Radiometer, to better understand Global Climate Models (GCMs) so we can improve our understanding of global warming,” Bill shared.

This technology was also recently used in the AirForce VAULT demonstration, which showcased the first terahertz air-to-air link with aircraft ranging up to 400 km in range. Commercial chip sales in this technology are also occurring for sensor and data applications.

The story of this chip starts with innovative thinkers like Bill, but was made possible by the advanced manufacturing processes Northrop Grumman is known for. Due to our expertise in this area, we have scaled critical dimensions onto a single device with unique characteristics which allow it to operate at high-frequency, and ultra- low power to meet the SWaP-C requirements for future DoD missions.

The ’Coolest Thing Made in California’

Los Angeles locals might have caught a glimpse of these chips on TV through squinted eyes as the technology was highlighted in a morning news broadcast as the CA Manufacturing and Technology Association was on the hunt for the ‘Coolest Thing Made in California.’

There were more than 130 submissions across the state; everything from edible cups to hypersonic vehicles. THz made it into the Top 16, then the Top 8 and finally to the Top 4 finalists, eventually winning the competition thanks to more than 200,000 votes: many of them our own Northrop Grumman employees.

The Coolest Thing Made in California; this tiny chip has provided recognition to hundreds of people working on this technology, the broader efforts of the NGMC and the trickle effect it’s having in the DoD and commercial markets.

Smaller than a grain of sand, and still defining possible.

Life at Northrop Grumman

Your work at Northrop Grumman makes a difference. Whether you want to design next-generation aircraft, harness digital technologies or build spacecraft that will return humanity to the moon, you’ll contribute to technology that’s transforming the world. Check out our career opportunities to see how you can help define possible.