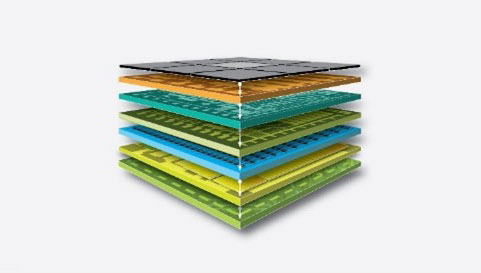

Our Super-Lattice Castellated Field Effect Transistor (SLCFET), invented at our Advanced Technology Lab, is a world-record, groundbreaking radio frequency (RF) switch. The change in traditional model led to a 3D layered structure which can handle a wider range of frequencies with minimal power loss, addressing a 30-year gap in RF switch advancement.

From Mops to Microelectronics

By: Rachael Tiehel

Squeesh, Squoosh. Paul Torres steps on and off the blue sticky floor outside a cleanroom, ready to start his engineering shift at the micro-line in Apopka, Florida. It’s a space where he now works on cutting-edge technology for the Northrop Grumman Microelectronics Center, but it’s also where his career at Northrop Grumman began — not long ago, he was installing that same sticky floor as part of the janitorial staff.

“This is where I want to be,” Paul says as he joins his engineering colleagues, down the hall from the janitor’s closet which once held the keys to his success.

Just the Beginning

In 2015, Paul moved from Puerto Rico to Orlando, Florida, determined to build a better life. A year later, he joined the U.S. Navy Reserves, seizing every opportunity he could find.

“Where I grew up in Puerto Rico was pretty rough, and without opportunity,” he said. “And when I moved here and saw signs for Northrop Grumman, I thought, ‘I’d like to work there.’

His dream became reality in 2017 when he was hired at Northrop Grumman in Apopka — as part of the janitorial staff. But that was just the beginning.

“I worked late hours, doing everything from making coffee to cleaning toilets,” Paul said. “But I knew I wanted more for my life and my family. I showed up every day for them.”

During those early years, Paul married, welcomed two children and pursued his education — often staying up late with his family after long shifts.

Building A New Life

Paul’s determination inspired those around him, especially his family.

“After I joined the Reserves, both my brothers joined the military, and my sister married an active-duty soldier,” he said. His success at Northrop Grumman only fueled their motivation further.

“I was working my janitorial shift and making small talk with a manager on the floor, when they asked, ‘How would you like to interview for a technician role?’ And as someone who always advocates for themselves, I knew this could be my chance, so I applied.”

In 2017, Paul transitioned to a temporary laser technician role, where he gained hands-on experience with optical-bonding, alignment, and testing electro-optic and infrared systems.

“I took classes in the day and worked second shift at Northrop Grumman,” he said.

In 2019, Paul became the first in his family to earn an associate’s degree. He continued his education, earning a bachelor’s degree in engineering technology and positioning himself for greater opportunities.

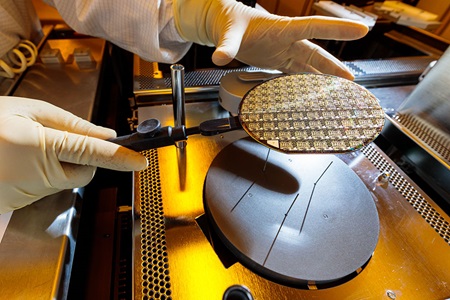

In 2023, Paul became a process engineer, working on microelectronics solutions for some of the company’s major captures. His work now involves inspecting semiconductor wafers with the Automated Optical Inspection (AOI) tool to create recipes, detect defects and report on yields to management and customers.

A Dream Job

“What’s my dream job?” Paul said. “I think I got it!” I would like to be a higher-level engineer someday, but I love the work I’m doing now.”

His rise from janitorial staff to engineer has inspired his coworkers.

“Paul’s ability to learn is infectious and you couldn’t ask for more from an employee,” said Ray Campbell, Paul’s manager. “He is always trying to improve himself, and the team really respects him. It takes a special person to navigate new opportunities, advocate for themselves and then go get what they want, and Paul has done that. “He doesn’t just want to be OK; he wants to be the best.”

Paul’s dedication has advanced his military career, as well. Today, he serves as an E6 Petty Officer First Class and the Leading Petty Officer of his unit.

Last year, he began studying for a master’s degree in software engineering, yet another reminder of how far he’s come.

Life at Northrop Grumman

Your work at Northrop Grumman makes a difference. Whether you want to design next-generation aircraft, harness digital technologies or build spacecraft that will return humanity to the moon, you’ll contribute to technology that’s transforming the world. Check out our career opportunities to see how you can help define possible.